Sleeving

Just thought people would be interested in seeing how my block resleeving came out (this is on an early s/n slatgrill block, hard to find, it was at .030, and needed to go to .060, and one cyl was badly damaged and would not clean up at .060, so I decided to sleeve the entire engine). The sleeves are the ones Mullins sells that have an ORD part number and were made in France. Regular generic sleeves do not have a step on the top or the taper on the bottom I think, they are just tubes that sit on a step machined into the bottom of the hole and have to be cut to length.

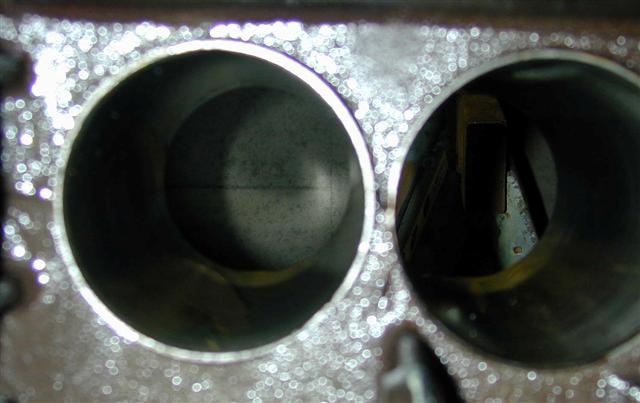

Here is the sleeve, it has a step at the top, and a taper at the inside of the bottom.

Here is the top of the block after surfacing, you can see the top of the sleeve step as well as new valve seats.

Here is the bottom inside (sorry, messed up on the focus)

I had a very good machinist do the sleeve installation.. he does tractor engines all day long… many with sleeves. He told me that he broke through the wall in one place… so that suggests that those people thinking of going 80 or 100 should think twice… Will try to find out the OD of these sleeves to provide data on how far you can go. He told me he coated the sleeves with some special sleeve sealant before inserting them. Suggest best place to take your engine in to such a place, not to your local hot-rod rebuilder.

I paid about $200 more to go the sleeve route (4 X $24 for the ORD sleeves, and it cost about another $100 in machine work)

Also, you can see on the right side between No. 3 and No. 4 that there is one headbolt hole that has a heli coil in it… the machinist installed it for me and said that there would be no problem.. would take the full head torque…

Here is a picture of Randy Helbling who did the work… just for fun… he is at the NAPA in Northfield Minnesota and has done many many MB engines for Louie Larson (retired, of Willys Mpls) over the years… His shop was very clean, and his instruments were handled with care… Be sure to look for a machinist who runs a clean shop along these lines… not one with a floor coverd with discarded parts and cuttings etc.

Turns out my crank was cracked… so it is a good idea to take your cranks to real crankshaft rebuilders, not your local machine shop… The place I had mine done does some fancy testing before grinding to look for cracks etc. Not sure if it is xray or magnaflux sort of thing, but they sure did a nice job on my crank… worth sending it to a place that just does cranks…

Here is a picture of the crack on the bad crank.. did not see it when I took it in to them, but they cleaned up the crank with chemicals and there it was…